Ilyushin IL-76MD-90A is a new military transport aircraft (code name: IL-476) developed by Ilyushin Aviation Complex, a subsidiary of United Aircraft Corporation (UAC). It is a modernised version of the IL-76MD which itself is based on the IL-76 cargo aircraft platform.

IL-76 cargo aircraft – Sputnik

IL-76 cargo aircraft – Sputnik

The IL-76MD-90A cargo aircraft is manufactured at the Aviastar-SP production facility in Ulyanovsk. The factory test flight of the first IL-76MD-90A was concluded in January 2013.

First experienced the upgraded transport plane Sludge-76MD-90A built an aircraft factory “Aviastar-SP”Ulyanovsk and preparing for flight tests.

First experienced the upgraded transport plane Sludge-76MD-90A built an aircraft factory “Aviastar-SP”Ulyanovsk and preparing for flight tests.

The aircraft successfully completed its maiden flight test in March 2013, near Moscow. It flew at altitudes of 2,000m to 10,000m for a period of one hour and 55 minutes during the test flight.

The flight test programme of IL-76MD-90A is expected to conclude by the third quarter of 2014.

IL-76MD-90A is developed to transport a range of military equipment, armed personnel, heavy and long size vehicles and cargoes. It will also be used in parachuting cargo / troops and other air borne cargo missions.

Orders and deliveries of the Russian military transport aircraft

The Russian Ministry of Defence (MoD) signed a $4bn contract with UAC for the delivery of 39 IL-76MD-90A aircraft, in October 2012. The deliveries are scheduled to commence in 2014.

Il-78M-90A Aerial Refuelling Tanker

The Il-78M-90A aerial refuelling aircraft is 46.6m-long, 14.76m-high, and has a maximum take-off weight (MTOW) of 220t. Its payload capacity has been increased to transport large volumes of fuel.

The wing assembly has been modified to incorporate two modern fuel tanks with a total capacity of 111,940l. The wing area and wing spans are 300m² and 50.5m respectively. The tanker accommodates six flight crew members.

The fuselage has a diameter of 4.8m and is configured to carry approximately 50,300l of fuel, while a large cargo ramp at the rear enables airdropping. The modular airframe can be converted to support other roles such as fire-fighting and cargo transportation.

The aircraft is outfitted with reinforced nose and main landing gear to support the increased maximum take-off weight (MTOW).

Refuelling capabilities of Il-78M-90A tanker

The Il-78M-90A refuelling aircraft carries a total of three UPAZ-1M hose and drogue aerial refuelling pods, two of which are mounted on the main wings and the remaining on the right side of rear fuselage. The fuel transfer capability of the UPAZ-1M pod is between 2,300l and 3,000l per minute.

Aerial-refueling system UPAZ-1M

ruaviation.com

ruaviation.com

Currently “RD&PE Zvezda” JSC designs and develops a unified aerial-refueling pod (UPAZ-1M) featuring an improved performance. The UPAZ-1М is to be mounted on the IL-78М-90А tanker.

The UPAZ-1М will support aerial refueling of the long-range, front-line and special aircraft equipped with aerial fuel-reception systems.

UPAZ-1 pod – redsamovar.com

UPAZ-1 pod – redsamovar.com

In comparison with earlier developed items (UPAZ,UPAZ-1), the UPAZ-1М has a higher pumping capacity (up to 3000 l/min) owing to introduction of the ТNА-150М turbo-pump assembly with a higher power turbine. It is planned to complement the UPAZ-1М with an electrically driven pumping station, an angular movement transducer and a fire alarm system, SОP-62.

ruaviation.com

ruaviation.com

In the UPAZ-1М, the automatics control system is supported by the BАI (Automatics & Data Unit). Application of the BАI, which is being created on the basis of a modern domestic processor, makes it feasible to:

- realize flexible adjustment of the UPAZ-1М operation algorithms by the BАI reprogramming;

- obtain digital channels for data exchange with aircraft systems and checkout equipment using any interfaces currently applied in the aircraft;

- equip the UPAZ-1М with a self-contained recorder to register the pod’s performance characteristics both in flight and during maintenance on ground.

In future, application of the BАI in the UPАZ-1М will make feasible an automatic system to control the aerial refueling parameters. Source zvezda-npp.ru

The wing-mounted pods allow inflight refuelling of two frontline aircraft such as MiG-29/35 and Su-27/30/34/35 simultaneously using TNA-150M turbo-pump unit, while the rear-mounted pod allows for the refuelling of a long-range or special aviation aircraft.

The aircraft has the ability to refuel up to four aircraft simultaneously on land. Source airforce-technology.com

Il-78M-90A refuelling aircraft PDF: Here

First Il-78M-90A tanker aircraft being rolled out to a flight testing

Russian AEW aircraft A-100 made its first flight: Here

A-100 AWACs – Image: UAC

A-100 AWACs – Image: UAC

Excerpt

The latest Russian aircraft radar patrol and targeting A-100 made in Saturday’s first flight, reported the press service of the concern “VEGA” (part of the holding Russian electronics of the state Corporation “rostec”), which develops the car.

Russian Il-76 “Candid” Modified To Support Special Operations Conducts Flight Test Over The Black Sea: Here

Excerpt

A really interesting aircraft was spotted conducting flight testing over the Black Sea on Sept. 26, 2017: the Il-76MD-90A “78650”, the first “Candid” modified to carry out special operations.

According to the Russian media outlet “Izvestia” the example “78650” is a flying testbed for a heavily modified Il-76MD-90A variant equipped with “unique on-board radio-electronic systems that would allow the aircraft to stealthily deliver paratroopers and special forces behind the enemy lines, remaining invisible and invulnerable to the enemy.”

How the aircraft can evade radars and remain invisible is unclear, anyway, the experimental Candid can be distinguished from the baseline IL-76MD-90A by the presence of an opto-electronic station mounted on the lower nose section of the aircraft and for the “President-C” system used designed to protect aircraft from MANPADS (Man-Portable Air Defense Systems) and IR (heat-seeking) missiles by laser and radiofrequency/electronic jamming of the missile guidance.

Il-76MD-90A Aircraft to Combine Static and Endurance Tests

Russian Ministry of Industry & Trade has financed development of procedure for static and endurance tests of transport airplanes. It will be based on results of design audit over Il-76MD-90A aircraft and integrated into the R&D project codenamed Opora.

According to the R&D project documents available to Mil.Today, after transfer of production facilities from the Tashkent Aircraft Production Company to Ulyanovsk-based Aviastar-SP, “emerged the need for radically new procedure for structural tests that would ensure conducting both static and endurance tests at the same facility”. That must reduce the trials time and costs

As of today, an endurance specimen of upgraded Il-76 has passed fatigue tests in the extent of up to 2,000 flights. Additional calculations and experimental studies shall prove the design service life of 8,000 flights, says the R&D project description. It is planned to finish the tests by the end of 2019.

Mikhail Pestrakov, an aviation engineer and an airspace expert, confirmed to Mil.Today that the in-depth upgrade of the airplane needs new endurance tests and high-tech methods of their studying.

“The aircraft testing procedure must be adjusted in step with technology development”, the expert said

Gen Maj Alexander Akhlyustin, Russia’s honored military pilot of Il-76 aircraft added that due to production transfer the equipment and staff had changed, so assembly technology might change as well, which gave rise for extra tests.

For reference

New version of Il-76MD-90A transport aircraft differs from the predecessors by several parameters. The plane has ‘glass cockpit’, new communications and protection system, and new piloting and navigation equipment. Besides, it has more powerful engines PS-90A-76 thrusting up to 14.5 tons, which helps the airplane lift up to 60 tons payload.

Service life of the new version of widely-known military transport aircraft reaches 30 years with an extension potential. The plane got upgraded wing and reinforced landing gear. Source mil.today

IL-76MD-90A design, based on the IL-76

The IL-76MD-90A is based on the same airframe and fuselage of IL-76 aircraft. The cargo aircraft integrates advanced features such as redesigned wing section, new cockpit with modern avionics and powerful engines.

The aircraft has a length of 46.6m, height of 14.76m, wing span of 50.50m and a wing area (trapezoidal) of 300m². The landing gear track (outer wheels) and fuselage mid-section diameter of the aircraft are 8.16m and 4.8m respectively.

The IL-76MD-90A has a maximum take-off weight of 210t and can carry a maximum payload of 52t. It can accommodate up to five crew members.

The heavy transport aircraft Il-76MD-90A is designed for inter-regional transportation heavy long-size cargoes. IL76MD-90A can be also used for transportation of ill and injured people and for fire-extinguishing purposes.

The maximum payload has been increased up to 52 tons.

The maximum takeoff weight has been increased to reach 210 tons.

The aircraft is a cantilever high-wing monoplane with four engines located on the wing pylons. It has a Tee-tail unit and a 5 leg-landing gear. A cargo compartment is located in the fuselage tail bottom section. It has a ramp for loading/unloading cargoes and equipment and for parachute dropping purposes.

The aircraft can perform takeoff and landing on unpaved airfields (with consistency of the soil up to 7.5 kg/cm2) and on concrete pavement airfields with altitude above sea level pending from minus 300 up to 3000 m and perform flights day and night over land and sea.

The aircraft upgrading envisaging installation of up-to-date engines, aircraft control systems, a new wing and a reinforced landing gear extends the Il-76MD-90A aircraft performance and increases the navigation and parachute dropping accuracy. Source aviastar-sp.ru

Cockpit and avionics of the Ilyushin aircraft

The advanced glass cockpit of the IL-76MD-90A is installed with three intelligent control panels and a KSEIS-KN-76 aircraft status master monitor display system with eight multifunctional liquid crystal displays. The glass cabin provides better view to the cabin crew.

Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva

Cockpit and integrated flight and navigation system

The “glass cabin” principle has been realized in the aircraft. Eight multifunctional LC displays and three intelligent control panels have been installed in the cockpit. The glass cockpit provides for excellent view from the pilot and navigator work stations. The new “Kupol-III-76M” flight sight navigation system is installed in the Il-76MD-90 aircraft to provide for solving navigation problems and intended for: work with navigation data bases also including the global base: when preparing the flight plan, during en-route flight, when maneuvering in the aerodrome area and during approach (SID/STAR, APPR); automation in solving navigation problems ensuring automated flight along the pre-planned path using autonomous and non-autonomous correction means; providing aircraft traffic collision avoidance; automatic approach according to category II to aerodromes equipped with landing facilities corresponding to ICAO category II; detection, identification with the help of weather radar and display on the integrated navigation status indicator the weather conditions in horizontal and vertical sections including the four color indication of precipitation intensity and turbulence in accordance with the ARINC-708A recommendations, detection of mountain peaks, big cities, detection of encountering aircraft by a passive method, detection and tracing of radar beacons, providing the inter-aircraft navigation mode; providing the system automated control on the land and in the flight. Source aviastar-sp.ru

The IL-76MD-90A also integrates a digital ACS-76 auto flight control system and a new Kupol-III-76M flight sight navigation system with a display indication.

Kupol navigation & ground surveillance radar

| General data: | |

|---|---|

| Type: Radar | Altitude Max: 0 m |

| Range Max: 64.8 km | Altitude Min: 0 m |

| Range Min: 0.4 km | Generation: Early 1970s |

| Properties: Pulse-only Radar |

| Sensors / EW: |

|---|

| Generic Weather Radar – Radar Role: Radar, Weather Max Range: 64.8 km |

Kupol-III-76M flight sight navigation system

T24

T24

IL-76MD-90A cargo handling capabilities

The cargo cabin of the aircraft is designed with a length of 24.5m (with ramp), width of 3.45m, and height of 3.4m. The cargo cabin offers an interior volume of 321m³.

ilyushin.org

ilyushin.org

Il-76MD-90A is capable of carrying 126 parachutists or 145 troops in single deck arrangement and 225 troops in double-deck arrangement. It can also be installed with special equipment to carry 114 injured persons.

The aircraft is installed with an Aerial-Delivery System (ADS) for dropping of cargoes, transportation of armed forces cargo containers and pallets, and troop parachutes.

Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva

The ADS installed onboard the IL-76MD-90A facilitates dropping of parachutists from an altitude of 8,000m at 220km/h to 400km/h speeds. It also enables equipment dropping with the help of parachutes from altitudes of 300m to 4,000m at 260km/h to 400km/h speeds.

Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva

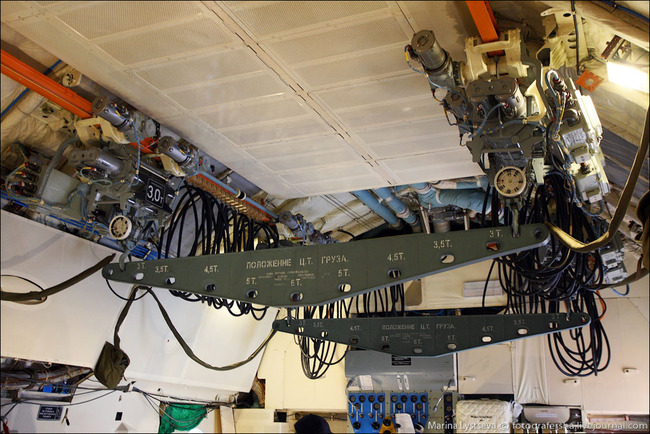

On the cargo compartment floor and ramps are installed with four roller monorail track in two versions: in special niches for landing platforms on the beams for the transport of air containers and pallets. Source survincity.com

The cargoes and equipment are loaded through the cargo door by means of airborne winches and electric overhead monorail motor hoists. Two winches ensure loading the dumb wheel equipment with maximum force on each winch cable to make up 3000 kgf. The winches are driven electrically and manually. The loading of a cargo item can be done with four hoists weighing up to 10 tons.

The cargo cabin has a ramp, which can be moved to horizontal or some other necessary position during loading and unloading operations. If needed, some cargoes weighing up to 30 tons can be lifted to the cargo cabin by means of a ramp. To load caterpillar and wheel vehicles as well as a platform, four under-ladder devices are to be installed onto the ramp to provide a smooth entering of the vehicles onto the ramp. Four roller ways are to be installed onto the cargo cabin and ramp floor with a monorail in two variants: in special niches for platform parachute dropping; onto the beams for transportation of aviation containers and pallets.

For carrying of people there are seats in the cargo cabin and the removable central seats can be installed. In the one-deck variant (with central seats) the aircraft can carry 145 men or 126 parachutists. In the two-deck variant it can carry up to 225 men.

The aircraft is equipped with the cargo dropping system that allows a single and serial dropping of platforms loaded with cargoes and equipment.

Besides that, in the cargo cabin some special equipment can be installed to ensure:

-

carrying of up to 114 injured people and the medical personnel

-

providing intensive therapy for up to 20 badly wounded people

-

fire extinguishing

Source aviastar-sp.ru

Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva

The cargo dropping system aboard the aircraft ensures the dropping of platforms laden with shipments and equipment. The under-ladder devices, roller ways and winches in the cabin allow the loading of cargoes and equipment into the aircraft.

Engine of Russia’s Ilyushin military cargo aircraft

IL-76MD-90A is installed with four fourth generation PS-90A-76 turbofan bypass engines with 4:4 bypass ratios. Each engine develops a maximum continuous thrust of 14,500kgf. It consumes 12% lesser fuel and offers an increased flight range of 18%.

4 x PS-90A-76 turbofan bypass engines

PS-90A-76 engine (PS – Pavel Soloviev) is a modification of PS-90A turbofan bypass engine. It extends service life of the large fleet of the IL-76 transport airplanes and raises their efficiency by installation of the PS-90A-76 engine instead of the D-30KP. It allowed to build a new modification of the IL-76 airplane – the IL-76MF military cargo aircraft which meets modern requirements.

Turbofan, bypass, two-shaft, mixed flow, with a thrust reverser in a fan duct and noise absorbing system.

It is intended for various versions of the IL-76 long-range cargo aircraft and the IL-76MF aircraft.The engine was certified in 2003.

Performance

Thrust, kg

|

14500 3500 |

| Specific fuel consumption (with real nozzle), kg/kgf hour | 0.595 |

| Flight altitude, m | up to 13100 |

| Air temperature at sea level (for start and operation), ° С | -47…+45 |

| Airfield height (versus sea level) , m | up to 3500 |

Wind speed for ground operation, no more, m/s

|

15 5 |

| Engine length, mm | 4964 |

| Fan tip diameter, mm | 1900 |

| Dry weight, kg | 2950 |

| Thrust reverser weight, kg | 450 |

| Delivery weight, kg | 4160 |

Advantages of the PS-90A-76 engine compared to D-30KP

- Conformity of ecological parameters on emission and noise to ICAO regulations

- Increase of reliability and life

- Improvement of efficiency

- Availability of thrust augmentation up to 16000 kg

- Parameter stability of running

- Improvement of fire safety in connection with replacement of some fuel accessory units by pneumatic

- Feasibility of the fan impeller replacement when running

Dimensions:

Cargo Compartment Height 3.4 m, Cargo Compartment Length 31.1 m, Cargo Compartment Width 3.5 m, Fuel Tank Capacity 109,500 l (28,816 gl), Fuselage Diameter 4.8 m, Height 14.3 m, Length 53.2 m, Payload Capacity 400 metric ton, Wing Area 300 square meter, Wingspan 50.5 m

Weights:

Max Weight 210 t, Payload 60 t

Engine/s Performance:

Thrust 141,000 lb (63,958 kg)

Performance:

Ceiling 12,000 m (39,370 ft), Cruise Speed 850 kph (528 mph), Landing Run Distance 990 m (3,248 ft), Max Range 6,300 km (3,402 nm) carrying a 40t payload or 4,000km carrying a 60t payload, Service Life 30 yr, Take Off Run Distance 1,800 m (5,906 ft)

Other:

Number of Engines 4, Service Life (Flight Hours) 30,000, Service Life (Flights) 10,000

Source generalequipment.info

Image: hiveminer.com

Image: hiveminer.com

The PS-90A-76 engine on board the IL-76MD-90A aircraft is compliant with latest ICAO requirements for noise and emission levels. An Auxiliary Power Unit (APU) TA-12A is installed onboard the aircraft.

TA-12A APU

TA12-60 is a single-shaft auxiliary gas-turbine engine with the equivalent power of 360 kWt. This engine is designed for aircraft and helicopter APUs. It is used for air turbine start of the helicopter and aircraft mid-flight engines, AC electric power of 115/200 V, power up to 60 kWA and providing air conditioning for cockpit and cabins.

High overall efficiency of the engine is based on the use of a 4-stage axial compressor. An annular reverse-flow combustion chamber of evaporative type provides 0,99 burning and low content of hydrocarbons in the exhaust gases. The engine contains a 3-stage axial turbine. Driving units, including alternator, are installed on the engine’s gearbox.

The noise level of the TA12-60 engine, when installed on the craft, does not exceed 90 dB.

The engine complies with the Norms of Aircraft Airworthiness (NLGS-3); this is confirmed by a type certificate No 101-VD issued by the Aviation Register of the IAC.

Since 2005 the TA 12-60 APU has been operated under the second strategy. The TA 12-60 APU is operated subject to the technical condition till the specified life time of the principle components is terminated (4,000 hr/starts).

The TA12-60 engine has been in serial production since 1996.

APPLICATION: Tu-204, Tu-214, Tu-334, Be-200, An-70, Yak-42.

Technical features:

| Absorbed electric power of AC, kVA | 60 |

| Bleed air consumption, kgf | 1,6 |

| Bleed air pressure, kgf/sm2 | 4,9 |

| Bleed air temperature, °С | 250 |

| Start and operation altitude, m | 7000/9000 |

| Environmental temperature, °С | ± 60 |

| Weight (without generator), kg | 297 |

| Specified number of operating hours/starts | 2000/4000 |

| Overall dimensions, mm | 1588х682х718 |

Source aerosila.ru

Performance of the IL-76MD-90A

Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva

The aircraft can cruise at a speed of 820-850km/h. It can fly at a maximum altitude of 12,000m. The maximum range of the aircraft is 8,500km. The aircraft requires 1,700m take-off distance on concrete runway.

The life expectancy of the IL-76MD-90A military transport aircraft is 30 years. The aircraft can accumulate a maximum of 30,000 flying hours throughout its service life.

Il-76MD-90A – Marina Lystseva

Il-76MD-90A – Marina Lystseva

Specifications (Il-76TD-90)

ilyushin.org

ilyushin.org

Characteristics

Overall geometry dimensions

| Length of the aircraft, m | 46,60 |

| Height of the parked aircraft, m | 14,76 |

| Wing span, m | 50,50 |

| Wing area (trapezoidal), m2 | 300,0 |

| Landing gear track (outer wheels), m | 8,16 |

| Fuselage mid-section diameter, m | 4,8 |

Characteristics of the turbofan bypass engine PS-90A-76

| Quantity of engine | 4 |

| Bypass ratio | 4,4 |

| Thrust, kgf | |

| Maximum continuous thrust | 14500 |

| Overspeed condition regime | 16000 |

| Cruising power | 3300 |

| Reverse thrust | 3600 |

| Compliance with ICAO requirements | п.16, Гл.IV |

| Specific fuel consumption at cruising power | 0,59 |

Weight characteristics

| Maximum takeoff weight, t | 210 |

| Maximum payload, t | 52 |

| Fuel tanks total capacity, l | 109500 |

Flight data

| Cruising speed, km/h | 820 … 850 |

| Flight range, km | |

| with 50 tons load | 4100 |

| with 40 tons load | 5400 |

| with 20 tons load | 8500 |

| Flight altitude, m | 9000…12000 |

| Takeoff ground run, m | 1450 |

| Takeoff distance required on the concrete runway, m | 1700 |

| Landing ground run when using engines thrust reverser, m | 930 |

Cargo cabin dimensions

| Length with ramp, m | 24,50 |

| Width, m | 3,45 |

| Height, m | 3,40 |

| Cargo cabin capacity, m3 | 321 |

Aircraft service life

| Calendar years | 30 |

| Number of landings | 10000 |

| Number of flying hours | 3 |

Source: aviastar-sp.ru/airforce-technology.com/flickr.com/photos/lystseva

Main image Alexander Kopitar – AviMedia

Updated Nov 11, 2020