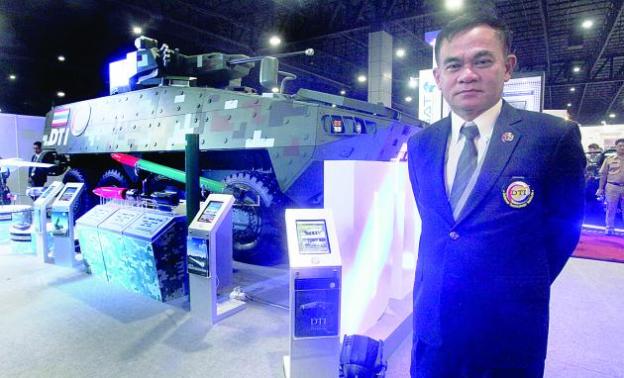

The Defence Technology Institute director, General Sompong Mukdasakul, shows off the DTI’s Black Widow Spider 8×8 armoured vehicle at the Defence & Security Exhibition 2015.

Wasamon Audjarint

The Nation November 16, 2015 1:00 am

The mean, green Black Widow Spider armoured personnel carrier had a commanding presence at the recent Defence & Security exhibition at the Impact Arena exhibition hall, attracting sideways glances from visitors awed by its 30-millimetre automatic canon, day and night mission electro-optical camera, and its eight giant rubber-based wheels.

The military behemoth took pride of place at the event not only because its fine lines lent it a sophisticated air, but also because it is the first vehicle of its kind ever to be built by the Army.

“It started a couple of years ago when we received an order from the Defence Ministry to develop an armoured car,” said General Sompong Mukdasakul, director of the Defence Technology Institute (DTI), who was responsible for the vehicle’s development. “By doing it on our own, we will be able to produce as many as we need. We don’t have to wait in a queue like we do when ordering from overseas.”

As an experienced combat veteran who has participated in a number of battles, including the Thai-Laotian Border War, the general underlined the need for the country to have well-prepared troops. This is also to combat possible future threats like global terrorism, not to mention the possibility of having to cooperate withAsean countries in national defence technology development.

“The troops of a country are just like the security guards of a house,” he said. “If we don’t have them, we’ll be instantly invaded by thieves.”

Sompong said the DTI, which is the ministry’s research and development centre, started to forge cooperation with other parties in order to accomplish this vehicle. A Public Private Partnership (PPP) was explored to support the project, he said.

Under this cooperation platform, the organisation received cooperation from various agencies, both public and private, including safety car producer Preechataworn Industry and the National Metal and Materials Technology Centre. Research labs from educational institutions such as Chulalongkorn University and King’s Mongkut Institute of Technology Ladkrabang also contributed to the vehicle’s research and development.

Some foreign agencies also took part in the project, the general said, but he insisted their identities had to be kept confidential.

Still, the DTI claims to have been responsible for 60 per cent of the technologies used to develop the vehicle. Sompong referred to the development as a “breakthrough” for the country’s automobile industry.

The DTI and its partners built the vehicle in a short period of time compared with the time it usually takes other countries, Sompong said. It usually takes more than a decade for other countries to achieve the same scale of work as they have to adhere to the North Atlantic Treaty Organization (NATO) Standardization Agreement.

When comparing costs and benefits, the general said imported and domestically-made armoured cars are not highly different in price, with both costing around Bt40 million baht. However, domestically-made armoured cars are more worthwhile considering long-term maintenance and further development.

What is vital, Sompong said, is cooperation with outsiders. Cooperation with foreign agencies is beneficial not only in saving time on research, he said, but also in bringing know-how to Thai employees, resulting in long-term development of technical knowledge.

“The enhanced knowledge will provide a good stimulus to the country’s overall economy,” the general said. “And now the government is increasing the research budget by as much as one per cent of the country’s GDP. I think that’s a good sign.” Having already launched its new vehicle, the DTI plans to complete full tests and enhancements on the vehicle by next year. However, even Sompong could not predict the fate of the Black Widow Spider 8×8. “We still have to see if the Defence Ministry will approve more orders on the car,” he said.

The development of the Black Widow Spider is seen by some military observers as another step towards the country’s self-reliance of military equipment and weapons. Since its establishment in 2007, the DTI has spent its time trying to develop a range of lightweight weapons including the DTI-2 Rocket 122-mm unmanned aerial vehicle and virtual shooting range simulators.

At present, the Army spends an annual budget of around Bt1 billion in weapons development, said the general.

“Carrying out research requires a lot of time and human resources,” he said. “And our country has for a long time been static in developing new research. Mostly, we bought technologies [from other countries] but hardly developed our own. We have the illusion that we are capable while other [countries] keep passing us.”

Looking proudly at the military monster he helped to create, Sompong hinted that the organisation would reveal its upcoming project next year. “It will be a floatable one,” he said.

“We are working with the Royal Thai Marine Corps to develop a massive, floatable vehicle. We already have a draft model. The final product should be finished next year,” Sompong said.

Source: The Nation