Altay is the third generation+ main battle tank (MBT) of the Republic of Turkey and is being indigenously developed under the Milli Tank Üretim Projesi ALTAY (MITÜP ALTAY) programme (Altay National Tank Project). Altay will be the first national MBT developed for the Turkish Land Forces Command (TLFC).

The Turkish National Main Battle Tank Project began in 2005. In September 2010 the conceptual design phase of Altay was completed. The tank is currently in the detailed design phase which is planned to take about 30 months. The first prototype is expected to be ready by 2015.

Turkey intends to build 250 MITÜP Altay MBTs initially, and ultimately produce 1,000 new tanks in four separate lots of 250 units. Altay will incorporate the most modern features of a tank. The Turkish MBT will have a crew of four – driver, gunner, loader and the commander.

Altay main battle tank development

The Undersecreteriat for Defense Industries (SSM) embarked on the National Tank project to improve the technical capabilities of Turkish defence and to increase the domestic contribution towards national defence.

The tank is named after the Army General Fahrettin Altay, who commanded the V Cavalry Corps during the Turkish War of Independence. Development of the Altay tank will be completed in three phases.

The Defence Industrial Executive Committee (SSIK), the Turkey’s defence industrial procurement decision-making body, selected the contractor Otokar in March 2007, through a competition.

The $500m contract includes design, development and integration of Altay and qualification of the tank through prototypes and testing.

South Korean K2 Black Panther

South Korean K2 Black Panther

South Korean K2 Black Panther

Work on the Altay project began in August 2008 at the Otokar factory and is projected for completion in 2016. Otokar will develop four prototypes for testing. Altay will use the technology systems developed for the South Korean K2 MBT by Hyundai Rotem. Serial production will begin after successful testing of the prototypes. Turkey will own the design and intellectual property rights.

Altay main battle tank design and features

A 3D image of Altay was revealed to the public in August 2010.

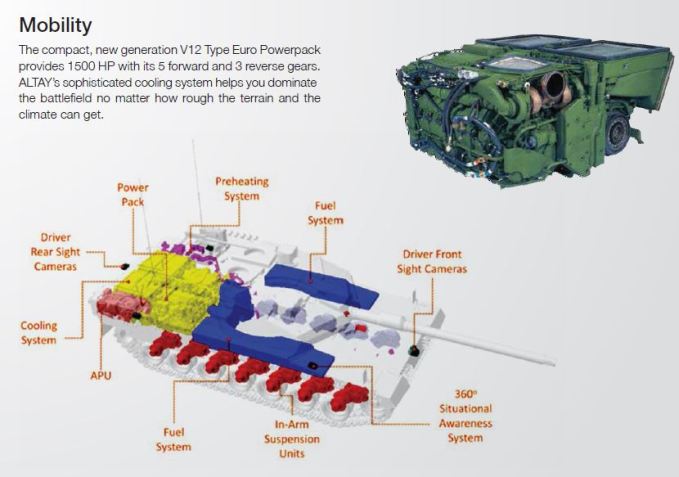

The tank will have a conventional layout. The power pack will be in the rear, driver seating in the front and fighting compartment in the middle. The loader will be on the left side of the turret, while the commander will sit on the right side of the turret. The gunner will sit on the same side as the commander but in a more forward and lower position.

Altay will have the stronger chassis characteristics of the K2 Black Panther MBT. It will have a re-designed Turkish turret and heavier armour than the K2. It will also have seven tracked wheels and a longer hull. A decision on the suspension system and other systems has yet to be finalised.

Fire control

The tank will use an advanced computerised Volkan-III modular (or National Cannon Fire Control System For Naval Platforms (TAKS)) fire-control system (FCS). It is being developed by Aselsan, which has partnered with STM, the software division of SSM, for developing the command, control and information systems.

Armament

120-mm / L55 smoothbore gun

120-mm / L55 smoothbore gun

120-mm / L55 smoothbore gun

Rheinmetall has developed a new 120 mm smoothbore gun with a calibre length of 55 (L55) which is a direct replacement for the current 120 mm smoothbore gun with a calibre length of 44 (L44) which is standard on all production Leopard 2 series MBTs.

This 120 mm L55 barrel is 1.30 m longer than the current barrel and this leads to a significant increase in muzzle velocity, especially with the latest APFSDS-T rounds which have more propellant and new penetrators.

The geometry of the chamber and the pressure limits are defined in the quadrilateral Interface Control Document (ICD) for the 120 mm tank main armament systems.

In accordance with the ICD, the Rheinmetall 120 mm L55 has the identical chamber geometry as the current fielded L44 barrel and complies with the pressure limits. This means that all current 120 mm projectiles can be fired from the new 120 mm L55 barrel.

In order to minimise the extent of the changes, the interface measurements of the 120 mm L55 to the breech and of the current 120 mm L44 to the cradle are unchanged. The weapon is fitted with a thermal sleeve, fume extractor and muzzle reference system.

120 mm/L55 Fume extractor

120 mm/L55 Fume extractor

According to Rheinmetall, two further improvements are possible with the latest 120 mm L55 barrel. First the breech could be made from the same steel as the barrel and this would increase the pressure load of the gun by 500 bar compared with the current L44 weapon.

Second, the design of the 120 mm L55 barrel permits a higher pressure load over a longer range of the barrel than is known from the fielded L44 barrel. So the new L55 barrel is prepared for future interior ballistics which are expected to show a wider maximum pressure instead of the now usual pressure peak.

During the extensive trials programme with prototype 120 mm L55 weapons, the hit accuracy was tested with existing ammunition as well as with the latest kinetic energy types such as the DM43A1 and the DM53. The results show the same dispersion characteristics as the current 120 mm L44. Trials have shown that the lengthening of the barrel results in an increase of muzzle energy of about 14 per cent when compared with the latest field APFSDS round.

It is expected that Germany and Netherlands will be the first countries to refit at least part of their current Leopard 2 fleet with the new L55 barrel. Source army-guide.com

120-mm / L55 smoothbore gun

120-mm / L55 smoothbore gun

120mm HE DM 11 Tank Ammunition

Rheinmetall developed its 120mm x 570 DM11 cartridge on behalf of the German MoD. From the technical standpoint, it is characterised first and foremost by the programmability of the chambered round and by its airburst capability. The necessary system modifications (programmability) can be retrofitted into any modern MBT with a 120mm smoothbore gun.

Modular in design, the DM11 consists of warhead with a programmable fuse as well as a ballistic cowl, tailfin assembly, drive band, combustible casing with propelling charge, and a newly designed case base containing the primer and an integrated data cable for programming.

The DM11 is designed for engaging lightly armoured targets such as vehicles, antitank positions (whether dug-in or in the open), field fortifications, double reinforced concrete walls as well as earth and timber bunkers . Furthermore, thanks to its high precision and maximum effective range of up to five kilometres, it can be used for penetrating barriers and engaging targets taking cover behind walls, etc., as well as for breeching enemy defences and creating avenues of approach for friendly forces in built-up areas. Source miltechmag.com

120mm KE DM63 / DM53 A1 Tank Ammunition

DM53 120mm KE Projectile (Rheinmetall)

The DM53 round was designed to maximize the performance of KE projectiles fired from 120mm smoothbore guns such as the L44 (15% improvement) or L55 (30% improvement in muzzle energy). The DM53 is in service with the German, Swiss and Netherlands Armies. The complete round weighs 21.4kg, the projectile (with sabot) weighs 8.35kg and propellant: 8.9kg. The projectile’s length is 745mm, and with chamner pressure of 5,450 generated during firing, the muzzle velocity is 1,750 m/sec (L55 barrel) and 1,670 m/sec. (L44 barrel). The DM53 has been optimized to lass than 0.2 mil accuracy.

DM 53-A1 is an advanced version of the DM 53. Currently being supplied in series to the armed forces of Germany, Austria and Turkey as the DM 63. DM53-A1 was selected by the armed forces of Finland and Denmark.

DM63 KE Cartridge (Rheinmetall)

The DM63 round is based on the DM53, with modified propulsion-based Temperature Independent Propulsion System (TIPS) utilizing the SCDB technology. The new type uses 8.45 kg of pure bulk powder to achieve nearly the same muzzle velocity of the DM53 (1,650 m./sec on L44 barrel). The propellant modifications aimed at improving the accuracy through a wide operational temperatures (-46 +63C) ensuring safe operation extreme climate zones, and minimizing the erosion of the barrel. Source defense-update.com

120mm PELE Tank Ammunition

PELE technology makes it possible to produce fully inert projectiles. The new technology modifies the projectile performance characteristics, significantly enhancing the accuracy of tank and artillery fire, while substantially reducing the risk of collateral damage. Non-explosive PELE ammunition consists of a high-density casing containing a core made of low-density, low-compressibility material. Upon impact with the target, the low-density material inside the shell is compressed to such an extent that the casing bursts, generating numerous fragments that are propelled in the direction of fire. This way, the round’s lethal impact is restricted to a defined space or limited area, reducing the likelihood of collateral damage. PELE and ALP make it possible to manufacture warheads containing little or no explosive. Moreover, existing ammunition can be inexpensively retrofitted with PELE and ALP technology. Both technologies can be integrated in full- and sub-caliber rounds, and fired from current and future weapon systems.

Image: from the web

Image: from the web

In August 2006 Rheinmetall Defense acquired the industrial property and trademark rights of PELE and ALP. According to Rheinmetall, the company plans to market them in conjunction with ammunition procurement and upgrade programs both at home and abroad. Concurrently, negotiations are underway with Diehl BGT Defence GmbH & Co. KG of Überlingen, Germany to acquire licenses in various special caliber segments. Source defense-update.com

Altay will be equipped with a 120mm L/55 smoothbore gun. It will be fitted with a muzzle reference system, a thermal sleeve and fume extractor. The ammunition will be stowed in the turret bustle with blow out panels on the roof. The tank will also have a 7.62mm machine gun mounted in coaxial to the right of the main armament. A 12.7mm heavy machine gun will be mounted on the right of the turret for commander operation.

A 12.7mm heavy machine gun

Roof-mounted 12.7-mm machine gun

Roof-mounted 12.7-mm machine gun

Self-protection

The front side of the tank will have special modular reactive composite armour protection. The tank will be designed to resist chemical, biological and radiological (CBR) attacks.

Both the gunner and the commander will be provided with stabilised day/thermal sights. They are expected to be incorporated with a laser range-finder having hunter-killer capability.

Aselsan “Active Protection System,” also known as AKKOR

Turkish military electronics giant Aselsan has unveiled a new active protection system, dubbed AKKOR (short for Aktif Koruma) at the IDEF’15 international defense fair in Istanbul. The system is intended primarily to provide Turkey’s indigenous Altay tanks with a hard-kill self defense capability, but it can also be used aboard AIFVs, APCs and other armored vehicles.

AKKOR features an impressive reaction time of only 1/15th of a second, allowing it to effectively defend the host platform against rockets and missiles fired from a distance as close as 50 meters (164 feet). It consists of three main components: a central processing unit that functions as the brain of the whole system, four M-band radar sensors and, typically, two projectile launchers capable of firing four smart interceptors. Each radar sensor continuously scans a 100-degree arc, creating a full 360 degree detection capability with some overlap. AKKOR’s radar plates, in their current configuration, can detect incoming threats with an elevation of up to 75 degrees, but vehicles can be integrated with an additional sensor on the roof as well for protection against top-attack missiles such as the Javelin.

What sets AKKOR apart from its competition is its smart interceptor. Most other hard-kill active protection systems detect an incoming threat, calculate its trajectory, find out when it will arrive at a certain point in space, and then fire a bunch of projectiles, typically steel balls (like a shotgun pellets), toward that general direction hoping that at least one of the steel balls will hit the threat and destroy it before it can make contact with the host platform. This technique, while simple and efficient, doesn’t protect against the newer generation, variable-velocity rockets and missiles that are designed to trick an active protection system into firing too early or too late, and consequently missing.

AKKOR, on the other hand, goes one step further. First, just like a legacy active protection system, it detects a threat, calculates its trajectory and aims towards a point in its path to intercept it — within a deviation allowance of less than 1 degree. Then, instead of firing a swarm of steel balls like its competition, AKKOR launches a single smart interceptor with its own on-board sensor, jointly developed by TUBITAK SAGE, and a high explosive warhead. Once activated, the interceptor continuously measures the distance between itself and the incoming threat during its short flight, detonates the high explosive warhead when it determines that it’s closest to the threat and effectively destroys it, all within the span of about one to two seconds. This method ensures the highest hit probability and effectiveness against both older and the newest generation anti-tank rockets and missiles.

“We’ve begun AKKOR’s development back in 2008 and successfully demonstrated the core technology behind it in a prototype back in 2010.” an Aselsan engineer explained at IDEF’15. “At the time, AKKOR proved effective against a HAR-55 projectile, also known as the M72 LAW.”

Aselsan aims to finish the development of the AKKOR system in time to field it aboard Turkey’s Altay main battle tanks and other armored vehicles. A lighter version, dubbed AKKOR Lite, and a naval version, AKKOR Naval, are being designed for use aboard lighter vehicles and by the navy respectively.

Aselsan hopes to sign a contract in the second half of 2015 with Turkey’s Undersecretariat for Defense Industries, the SSM, for further field tests. Serial production is expected to start in 2017 so that the system be can made available for the country’s first batch of 250 Altay main battle tanks. Source trdefence.com

Propulsion

BATU engine developed by BMC Power

MTU 883 diesel

| Engine model | MT 883 Ka-500 | |||

| Rated power max. | kW (bhp) | 1100 () | ||

| Speed max. | rpm | 2700 | ||

| Dimensions and masses | ||||

| Length (L) | mm (in) | 1488 (58,6) | ||

| Width |

mm (in) | 972 (38,3) | ||

| Height (H) | mm (in) | 742 (29,2) | ||

| Mass (dry) | kg (lbs) | 1800 (3968) | ||

| Engine main data | ||||

| Bore/Stroke | mm (in) | 144/140 (5,7/5,5) | ||

| Cylinder displacement | l | 2,28 | ||

| Displacement, total | l (cu in) | 27,4 (1672) | ||

Source mtu-online.com

The first two batches of Altay tanks will be powered by MTU Friedrichshafen 1,500hp (1,100kW) diesel engines. The engine will be coupled to a Renk transmission. An indigenous 1,800hp (1,300kW) engine is currently under development in Turkey and will be used in the last two batches of the tank. The tank will have a maximum speed of 70km/h and manoeuvrability at depths of 4.1m in water.

Contractors

Koç Group company Otokar is the main contractor for the Altay MBT development programme. The technology systems transfer licensing will be provided by Hyundai Rotem, which will also offer technical support and assistance in the tank development.

Aselsan will be responsible for the sub-systems and fire control system. The state-owned ammunition producer Makine ve Kimya Endustrisi Kurumu (MKE) will produce the main gun system, while Roketsan will develop and produce the armour package. The subcontractors will be responsible for integration of the respective equipment in the tank in cooperation with Otokar.

Image: armyrecognition.com

Image: armyrecognition.com

| Country of origin | Turkey |

| Entered service | Expected in 2016 |

| Crew | 4 men |

| Dimensions and weight | |

| Weight | ~ 55 t |

| Length (gun forward) | ~ 10 m |

| Hull length | ~ 7.7 m |

| Width | ~ 3.6 m |

| Height | ~ 2.5 m |

| Armament | |

| Main gun | 120 mm smoothbore |

| Machine guns | 1 x 12.7 mm, 2 x 7.62 mm |

| Elevation range | ? |

| Traverse range | 360 degrees |

| Ammunition load | |

| Main gun | ~ 40 rounds |

| Machine guns | ? |

| Mobility | |

| Engine | MTU 883 diesel |

| Engine power | 1 500 hp |

| Maximum road speed | 70 km/h |

| Range | ~ 500 km |

| Maneuverability | |

| Gradient | 60% |

| Side slope | 30% |

| Vertical step | ~ 1 m |

| Trench | ~ 2.8 m |

| Fording | ~ 1.2 m |

| Fording (with preparation) | 4.1 m |

Technical data military-today.com

Main material source army-technology.com

Images are from public domain unless otherwise stated

Updated Jan 23, 2017